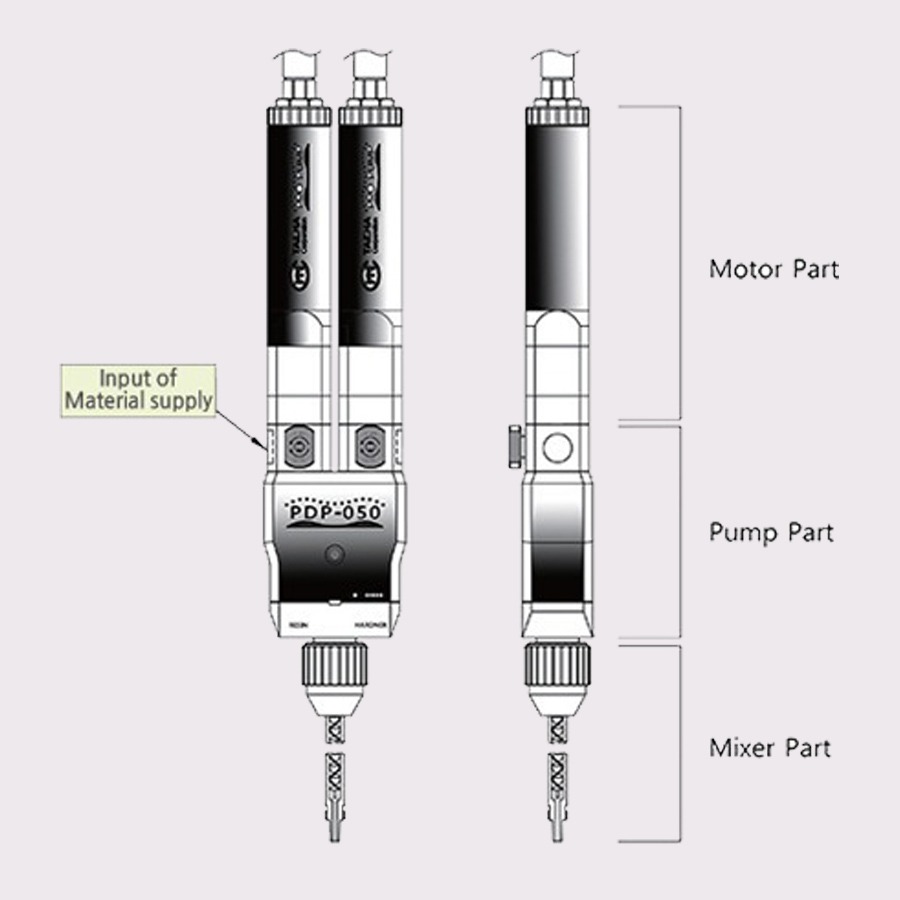

TAEHA PRO-DUO Pump System

TAEHA PRO-DUO Pump System

- An innovative dispensing system for handling 2K components, Taeha ProDuo is the ideal solution for meter mix applications. With an endless cavity principal the system can handle a wide variety of materials from low to high viscosities.

- It can also dispense micro-dots along with large volume requirements for various potting applications.

- The controller comes with a HMI with touch screen which helps in easy programming.

Features

- Consistent and long dosing by special progressive cavity pump structure.

- Simple adjustment of mixing ratio and dosing volume.

- Wide range of dosing regardless of difference of viscosity and mixing ratio.

- Clean dosing without leaking at the end of nozzle.

- Economical dosing by easy maintenance and eco friendly Controller.

- Precise & various dosing by exclusive software for 2- component system

- Color touch screen with user friendly interface & high data recognition

- Memory function for complicated and various dosing

- External interface function for continuously various dosing

- Easy controller by intuitively setting and data change

Specification

- Power IN/OUT- AC220, 50/60Hz/DC-24V

- Power consumption- 200W

- Operating mode- Time/Steady/ Auto cycle/

- Ratio Memory- 16CH

- Interface- RS232, D-SUB 9 PIN

- Input Signal- Contact input or NPN open collector

- Display- Contact Input or NPN open collector Air IN/Out- Ø6 Air hose/Auto jointer

- Pressure Regulator- 0-7 Kgf/cm Weight- 3.6kg

DISPENSER SPECIFICATIONS

| ITEM | PDP-015 | PDP-050 | PDP-150 | PDP-500 | PDP-1000 | PDP-1500 |

| Input Pressure | 0-6 kgf/cm3 | 0-6 kgf/cm3 | 0-6 kgf/cm3 | 0-6 kgf/cm3 | 0-6 kgf/cm3 | 0-6 kgf/cm3 |

| Max. Dosing Pressure | 20kgf/cm3 | 20kgf/cm3 | 20kgf/cm3 | 15kgf/cm3 | 15kgf/cm3 | 20kgf/cm3 |

| Viscosity cPs | 1~500,000cPs | 1~500,000cPs | 1~500,000cPs | 1~500,000cPs | 1~500,000cPs | 1~500,000cPs |

| Motor Speed(rpm) | 1~120 rpm | 1~120 rpm | 1~120 rpm | 1~120 rpm | 1~120 rpm | 1~150 rpm |

| Min. Dosing Volume | 0.0003 ml | 0.001ml | 0.003ml | 0.009ml | 0.009ml | 0.03ml |

| Accuracy of dosing | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Mixture Ratio | 1:1~10:1 | 1:1~10:1 | 1:1~10:1 | 1:1~10:1 | 1:1~10:1 | 1:1~10:1 |

| Material Inlet Port | G 1/8″ (STD) | G 1/8″ (STD) | G 1/4″ (STD) | G 1/4″ (STD) | G 1/4″ (STD) | G 3/8″ (STD) |

| Material output port | Luer lock | Luer lock | Luer lock | Luer lock | Luer lock | Luer lock |

| Wetting part material | SUS/ UHMW-PE/FKM | SUS/ UHMW-PE/FKM | SUS/ UHMW-PE/FKM | SUS/ UHMW-PE/FKM | SUS/ UHMW-PE/FKM | SUS/ UHMW-PE/FKM |

Exploring the Multifaceted Impact of the Pro-Duo Pump System in Diverse Industries

Why Choose Sumitron ?